B

L

I

S

T

E

R

Blister Track and Trace

The solution

Primary pack serialization and aggregation: an innovative yet practical solution for safer products. Find out more.

Reel

Printing

Printing

In line or off-line process? It’s up to you.

The software can manage the printing process directly in line, on the blister thermoformer, or using an offline Roll2Roll machine.

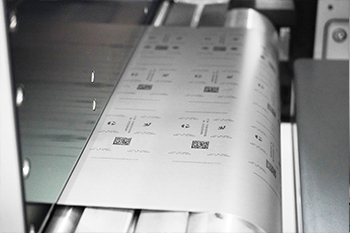

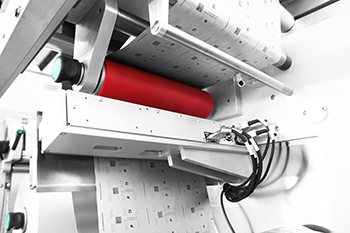

In-line printing

Print and check your reels in-line for the maximum flexibility and late-stage customization.

Off line reel printing

Prepare your reels in-house at a later stage without worrying about stocks.

Flexibility and optimal control in-line or off-line, at high speed

The software’s print quality verification algorithms work at high-speed, reaching the highest levels of performance both in terms of printing and inspection.

Serialize your reels with excellent printing accuracy and inspection reliability.

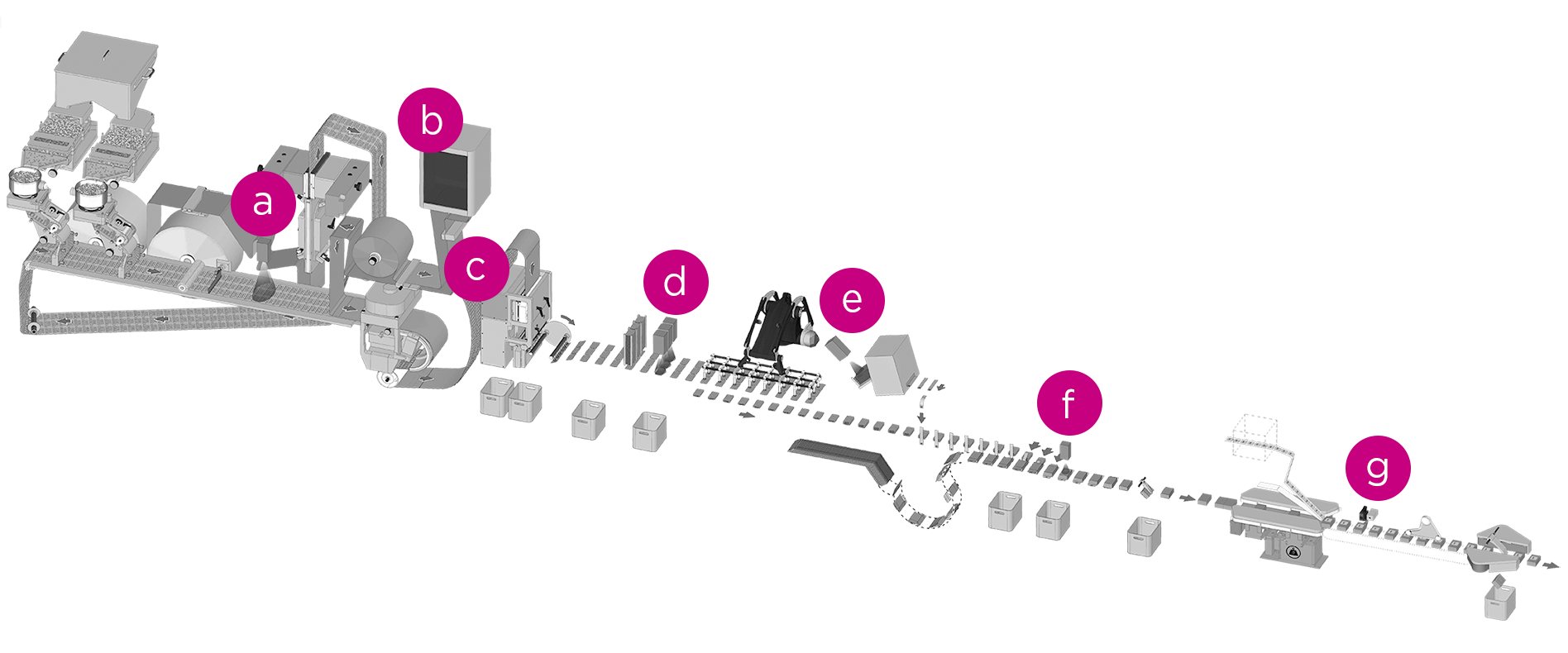

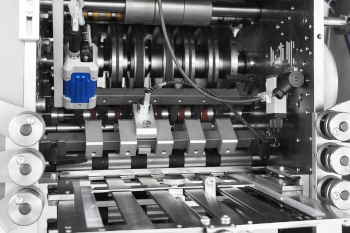

Blister packaging and aggregation to carton

a.camera 1

Product presence in blister. Product correctness. Damaged products, wrong colour, shape and size.

b.printer

In-line reel printing

c.camera 2

Artwork, codes and variable data control on reel made with a contact image sensor

d.camera 3-4-5

Blister / single pocket code control. Data matrix control on blisters or on single pockets for carton aggregation.

e.camera 6

Leaflet Pharmacode control.

f.camera 7

Verification of pharmacode on carton flap.

g.camera 8

Printing and verification of serialized data matrix and variable data (GTIN, serial number, batch number, expiry date). Blister to carton aggregation is now complete.

Aggregation to carton

You've joined the final step.

After serializing the primary packaging, it’s now time for blister-to-carton aggregation.

The last mile for total safety

At this stage, the 3-axis Robocombi robot developed by Marchesini Group transfers the blisters into the product conveyor for their insertion into the cartons. Programmable to perform different stacking sequences according to the blister count set, the Robocombi is controlled by software to automatically synchronise the transfer, tracking and stacking system. This technology, together with SEA Vision traceability software, ensures perfect aggregation.

Reach total traceability

Total data control done by SEA Vision traceability software and its integration into the Marchesini Group lines is extending its range of application, not only from carton to pallet, but also from primary to secondary packaging, thus ensuring 100% traceability.

Want to be ahead of the game?

This blister track and trace solution is strategic when drugs are dispensed in single doses.

Why?

Because when drugs are dispensed in hospitals, pharmacies - or they are in the hands of the consumer for personal use - the primary and secondary packaging are often separated.

Without aggregation, the primary packaging of drugs is still at risk of counterfeiting.

The answer to this challenge is to serialize the blisters and associate them with their cartons through aggregation. With thousands of software applications and machines installed around the world, the joint expertise and technological developments of SEA Vision and Marchesini Group together make it possible to reach amazing new results in terms of total safety and efficiency, and to fight counterfeiting.

Scan the

blister

blister

SEA Vision S.r.l. a socio unico, via Treves 9E - 27100 Pavia (Pv) Italy VAT N. IT01638840189 Corporate Registration Number: PV-199274 Share Capital: Euro 100.000